3D Modeling in Product Design: Guide for Innovators & Creators

3D modeling in product design is more than just showing potential customers a “complete picture”. By its nature, 3D modeling plays a critical role in how products are imagined, created, and brought to life. However, it is also about efficient workflows, crystal-clear visualization, and seamless collaboration.

So whether you're a product designer, engineer, or a company looking to streamline your development process, understanding how 3D modeling contributes to product design is the first step to boosting your efficiency and creativity.

Benefits of 3D Modeling in Product Design

Making 3D modeling part of your product design workflow has several benefits and impacts:

-

Visualization of concepts: 3D modeling allows you to make realistic renderings of your product ideas. Realistic product renders help stakeholders grasp the aesthetics and functionality even before manufacture. There’s less guesswork and more informed decisions thanks to realistic renders.

-

Prototyping and testing: Using digital models, rapid prototyping and testing is made quick and easy, as everything is done virtually. You can quickly identify flaws and areas for improvement without incurring expenses related to making the physical mock-ups, nor does it consume a lot of your time.

-

Reducing design errors and costs: 3D modeling can help you catch errors in the 3D design phase, which dramatically reduces the likelihood of costly mistakes during manufacturing.

-

Enhancing collaboration among teams: 3D models are a visual representation, so anyone can look at them and understand what the product looks like. It’s very much like a universal connecting language that helps design teams communicate their ideas better and collaborate with different departments and external partners.

3D Modeling Tools and Software

There are a diverse range of powerful 3D modeling software available for 3D artists today; each of them with their own unique strengths. Below are some of the most popular software for creating product models:

-

Autodesk Maya: Popular for its advanced animation and rendering capabilities. Maya also has more modern features like automation, collaboration and machine learning for smoother workflows.

-

Blender:It comes with a comprehensive set of tools for modeling, sculpting, animation, and rendering.

-

3ds Max: It’s a professional 3D modelling, rendering and animation software commonly used for 3D architectural rendering and game development, and has a hearty set of features for modeling.

-

SolidWorks: A popular 2D and 3D product development tool preferred by businesses, mechanical engineers and product designers for its precision and functionality in CAD models.

-

AutoCAD: Although known mostly for 2D drafting, AutoCAD has powerful 3D modeling features that make it a versatile tool for product design and engineering.

-

SketchUp: A 3D modeling software known for its ease of use and is used mainly for architectural, interior design, and product design projects. There are both free and paid versions, among which SketchUp Free is a great option for beginners.

Your choice of software should depend on the specific industry, project requirements, and desired level of detail. Here’s a comparison table of the software listed for a better understanding:

| Software & Pricing | Ideal Use Cases | Key Features |

|---|---|---|

| Autodesk Maya Paid (subscription-based) |

Product marketing, animation | Advanced animation, rigging, and simulation tools. Powerful organic and character modeling. Industry standard for large studios. |

| Autodesk 3ds Max Paid (subscription-based) |

Industrial design, architecture | Excellent for detailed, hard-surface modeling. Strong rendering capabilities (includes Arnold renderer). Robust plugin ecosystem |

| Blender Free, open source |

Digital prototyping, animation | Free and open-source. Great for beginners. A full 3D pipeline including modeling, rigging, rendering, and video editing. Strong community support and frequent updates. |

| AutoCAD Paid (subscription-based) |

Architecture, engineering, manufacturing | Focuses on 2D and 3D precision for documentation and manufacturing. Uses solid modeling for objects with accurate dimensions. Seamless integration with other Autodesk products. |

| SketchUp Subscription-based (with a free web version) |

Interior design, furniture design, architecture | Very user-friendly and beginner-friendly interface. Features like the "Push/Pull" tool for quick 3D form creation. Large library of pre-made models via 3D Warehouse. |

| SolidWorks Paid (subscription-based) |

Mechanical, industrial products | Known for its ease of use and ability to create precise, functional models. Specializes in producing professional, photo-quality images and animations from CAD data. |

Applications of 3D Product Modeling in Various Industries

3D modeling is so versatile that it is used in and benefits more than just a single industry. When it comes to product design specifically, the below are some of the industries that really benefit from using 3D modeling:

-

Consumer products

3D modeling helps design visually appealing and ergonomically-sound products, from electronics to apparel, automobiles and furniture.

-

Healthcare and medical devices

3D product design is used to create complex, ergonomic, and safe medical instruments, surgical tools and prosthetics (even used in surgical planning!).

-

Architecture and interior design

Architects, interior designers and real estate agents use 3D models to create realistic walkthroughs and 3D visualizations of properties which improve client approval rates (quicker sales in the case of property listings).

-

Automotive and aerospace

3D modeling is used quite extensively for designing vehicles, aircraft and intricate components. 3D CAD models here ensure precision engineering, simulation under stress conditions and improved designs for quality performance and safety.

Understanding the 3D Modeling Workflow in Product Design

The typical 3D modeling workflow in product design follows a structured path:

-

Conceptualization and Sketching

When creating a new product, the critical first step is ideation. It is the conception stage where we make the initial sketches (digitally or on paper) to define the product's form (looks) and function. The sketches are mostly rough and will be perfected as it goes through the 3D design process.

-

Digital Modeling

Designers then use CAD software or 3D modeling software to turn the sketches into a 3D digital model. The models (also known as digital twins) are detailed, dimensionally accurate and properly display product features, materials and surface details.

-

Texturing and Material Mapping

In texturing, after the model is ready, materials, colors, finishes, and textures are applied to the surface. The details we add to the surface (scratches, reflections etc.) and material characteristics (shiny, dull, matte etc.) are crucial for achieving realism and conveying how the final product will look under various lighting conditions.

-

Rendering and Visualization

Once the model is textured, the model is rendered into high-quality photorealistic product images that showcase its appearance and highlight the features in the best way possible. They’re pretty useful for marketing and stakeholder approval.

-

Prototyping and 3D Printing

Once the model is finalized, it can be exported as STL files for 3D printing and functional testing. In some cases, 3D printing is the final step as the printed goods are the final products. In other cases, the printed products are prototypes that are going to be put through tactile assessment and further refinement. For example, Nike used AI-powered 3D modeling and 3D printing as part of their Project AIR to create stunning shoe designs for athletes.

Because it is relatively quick to make edits to the models and print more prototypes for testing, it allows businesses to quickly bring products to market.

3D Product Visualization and Rendering

For computerized product visualization, 3D rendering is a vital process because it generates the photorealistic images or animations you want to make it a powerful marketing and sales tool.

Techniques for realistic product images

Product visualization has come a long way over the years. They’ve gone from looking fake and “plastic” to looking so real and convincing, and advanced rendering techniques (and rendering software) are a big part of the journey.

Some of the techniques used to get realistic renders are:

- Ray Tracing: A rendering method that simulates the path light rays take to create accurate reflections, refractions and shadows. It’s well-known for producing photorealistic results. However, it can be computationally intensive.

- Global Illumination: It’s a technique that simulates the way light bounces around a scene, affecting the overall illumination and appearance of objects and a scene.

- Physically Based Rendering (PBR): It simulates how light interacts with surfaces in a physically accurate way, which creates more realistic and predictable material appearances.

Use of 3D Animation and Virtual Tours in Marketing

As a way to complete the realistic feel of a product render, many businesses choose to animate the models or create virtual tours.

Why? It’s for the simple reason that you can create immersive experiences (using interactive 3D content) for potential customers where they can explore products from every angle and understand their features. 3D product marketing is brilliant for improving the online shopping experience.

Current Trends in 3D Modeling for Product Design

So long as technology evolves, the techniques that rely on them will also change and get better. In that respect, the following are some of the newest trends in 3D product visualization:

-

Integration with AR/VR

Augmented reality (AR) and virtual reality (VR) are already in business, like in eCommerce listings. In the context of product design, designers are using AR product visualization to position digital product models in real-world settings, collaborate with teams, work on the designs and instantly assess the impact of the physical environment.

In VR, designers are placed in completely virtual worlds, where they can examine intricate products. It’s a deeper level of immersion – compared to AR – that makes designers more creative and able to execute better-informed decisions while working.

-

AI-Assisted Design

Artificial intelligence (AI) is already making waves in various industries, and 3D product modeling is no different. It is already in use, automating repetitive tasks, generating design variations and optimizing product designs for performance. These days, you get AI-powered tools for both modeling and texturing, which otherwise takes up a huge chunk of a designer’s time. Not only is it faster, it is also easier, considering you can generate models with text prompts (text-to-3D models) or input images to generate textures (image-to-3D textures).

-

Sustainable Product Modeling

It is when you design and produce 3D models with as little environmental impact as possible. Some important features of this trend include

- Material selection: Using sustainable 3D printing materials like recyclable, biodegradable, or bio-based materials like PLA (polylactic acid) or recycled plastics.

- Design optimization: Reducing polygon count, simplifying the geometry and optimizing meshes to reduce the amount of materials that will be consumed and computational resources required for 3D product rendering.

- Waste reduction: Designing the product in a way that minimizes material waste.

- Digital workflows: Using both 3D modeling and rendering for virtual prototyping, collaborating remotely and reducing the need for physical prototypes and transportation.

- Energy efficiency: Optimizing designs for energy efficiency, like making provisions for natural light and ventilation in architectural models.

- Product lifecycle management: Considering the environmental impact of the product from production to disposal, including material sourcing, manufacturing processes, and end-of-life options.

Real-World Examples: Case Studies in 3D Product Success

-

Amazon

Anyone who uses Amazon will have come across 360-degree product views or even their AR-powered virtual “try ons”. This is how Amazon uses 3D product models to enhance a customer’s online shopping experience.

According to Amazon, product pages with 3D views or virtual try-on (AR) features see a 20% lower return rate.

Amazon’s average return rate is somewhere between 5% and 15%, but it depends on the category. Clothing and apparel have a much higher return rate – around 20-30% – due to sizing and fit issues. Electronics can be between 15-25%. In 2021, Amazon’s net sales were $469 billion. Considering the huge volume of sales they do, even a 5% return rate is no laughing matter. So, if 3D can bring about a 20% reduction in returns, it saves them a lot in associated costs.

Note: As of January 20, 2025, Amazon has discontinued the 360-degree image experience on product detail pages. Sellers can no longer upload new 360-degree images to their listings. Amazon now focuses on 3D models and interactive experiences like "View in 3D" and "View in Your Room".

-

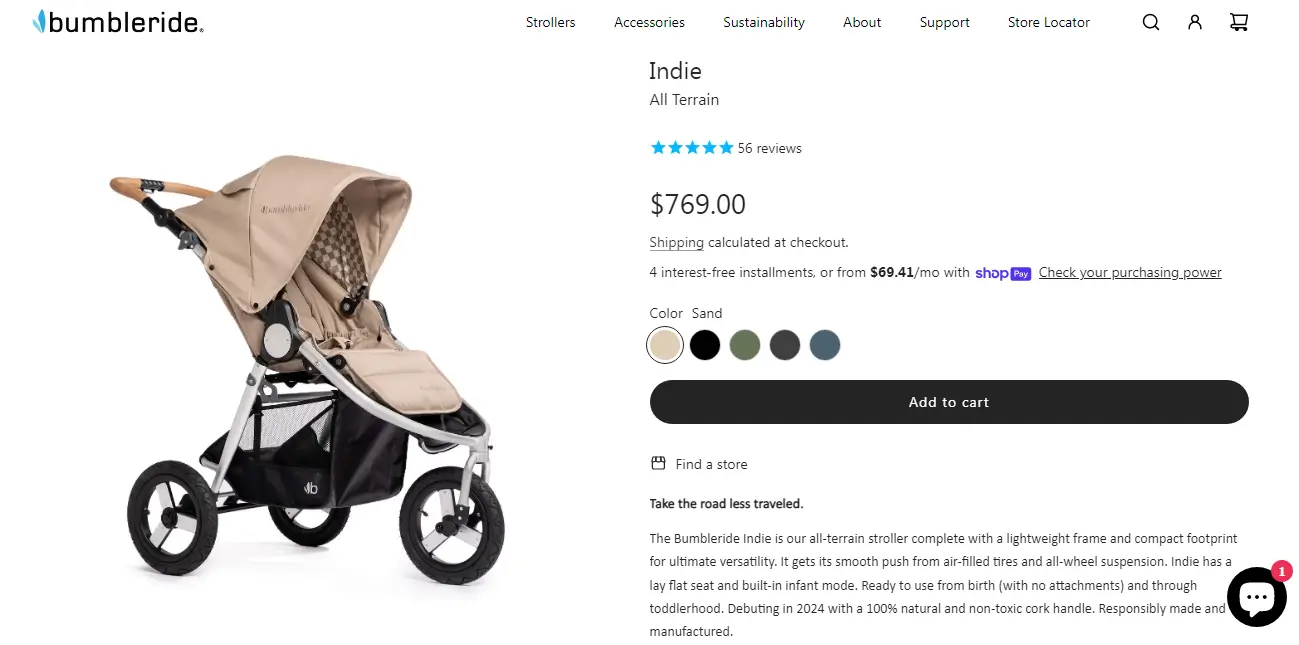

Bumbleride

Bumbleride (an eco-friendly stroller retailer) uses 3D and AR to allow potential customers to test out strollers in real-time. Parents-to-be can see, among other things, the space the stroller will take in their home, color options, texture and more. It leads to a more informed purchase decision for the parents, who are already pretty cautious about what they spend on.

What were the results?

- A 33% increase in conversion rates for their strollers

- A 21% jump in average time spent by visitors on their online shop

-

Strati: The world’s first 3D-printed car

Strati (Italian for “layers”), is the world’s first 3D-printed car, developed and produced by Local Motors and manufactured by Oak Ridge National Laboratory and Cincinnati Incorporated. It’s an electric car made with a large scale 3D printer developed by ORNL and Cincinnati Inc. and was unveiled at the International Manufacturing Technology Show (IMTS) in Chicago in 2014.

What is so special about the Strati – apart from the fact that it was 3D printed?

- It was printed in just 44 hours. CNC milling took 1 day and assembly took 2 days.

- The body has around 49 large printed parts. Traditional vehicles have around 30,000 parts.

- The design was crowdsourced. There were over 200 entries from more than 30 countries and the winning concept was submitted by Michele Anoè.

- They used a Big Area Additive Manufacturing (BAAM) machine developed jointly by ORNL and CI. It was a giant gantry-type FDM printer capable of extruding carbon-fiber-reinforced ABS.

- Materials used were ABS mixed with 20% chopped carbon fiber, which improved strength and reduced thermal warping.

- It weighed approx. 1,400 lb (≈ 635 kg) and had a top speed of 40 mph (≈ 64 kmph).

Why does Strati matter?

- It proves that a full-size vehicle chassis can be produced via 3D printing and driven off the production floor.

- It shows how micro-factory production (rapid iteration) —print, finish, and assemble vehicles – can be done in just days.

- It demonstrated the value of carbon-fiber-enhanced thermoplastics in large-scale additive manufacturing (another name for 3D printing).

- It made way for advanced applications like the autonomous bus Olli, which also used additive manufacturing in its build.

To Wrap This Up

3D modeling in product design has gone from being a luxury to a vital part of the manufacturing and marketing processes.

Here’s why… It makes everything, from CGI visualization to product development efficiency innovative marketing, better. Right from sketching to interactive virtual product tours and 3D-prints, the technology drives excellence, sustainability, and business success.

Whether you're just getting started or want to scale your 3D product development process, invest in the right tools, practices, and content strategies to set you apart from everyone else. If you lack the skills, infrastructure, and equipment, outsourcing your 3D product modeling requirements is a doable option.